Simple Elegant Solutions

Watch the video of this post.

Listen to the podcast of this post.

Last century I was a young Chemical Engineering Co-op student. I got to do my first professional gig as a Chemical Engineering after just one year of Freshman Engineering curriculum under my belt. Freshman Calculus, Chemistry, English. Hardly qualified to do any real engineering work.

Nonetheless, I travelled from my hometown of Cincinnati to Corning, New York. Headquarters for Corning Glass Works.

I was reminded over and over that I was Corning's first Co-op student. A Talent Experiment for this small Chemical Engineering department which serviced all of Corning's locations and diverse products: light bulbs, micro-sized medical products, lab benchtops, Corelle, Pyrex, resistors and capacitors for computers, Steuben fine crystal, optical wave fiber, on and on.

I quickly got enthralled with the unique qualities of glass. Did you know that glass is an amorphous solid? It exists in neither solid nor liquid state. Somewhere in between.

Pete was my supervisor on that first project. That summer, I learned as much about life as I did about glass and chemical engineering from Pete. He had a dream: to live on a property with minimal inputs from the world. He showed me plans for the simple cabin and how he streamlined all inputs down to salt and kerosene.

Clearly, Pete LOVED to streamline solutions to their simplest form. His solutions required deep understanding of the problem. Creative calculations. And a sharp mind that cuts through confusion and ambiguity to see things from a particular point of view. Always striving for that Simplicity.

Pete taught me about Simple Elegant Solutions.

In the orientation week, he introduced me to Simple Elegant Solutions on a plant tour where Corning manufactured Corelle. Corelle is a line of dishes that is nearly unbreakable.

Get ready for a little geekdom. What makes Corelle unbreakable? The plates are laminated with three layers of thermally-bound glass. The three-layer combination of different glass treatments applied at different temperatures provides a surface tension that makes it nearly impervious to impact. You can bang it around quite vigorously and it doesn't break. But when it goes, WOW, it shatters into millions of pieces.

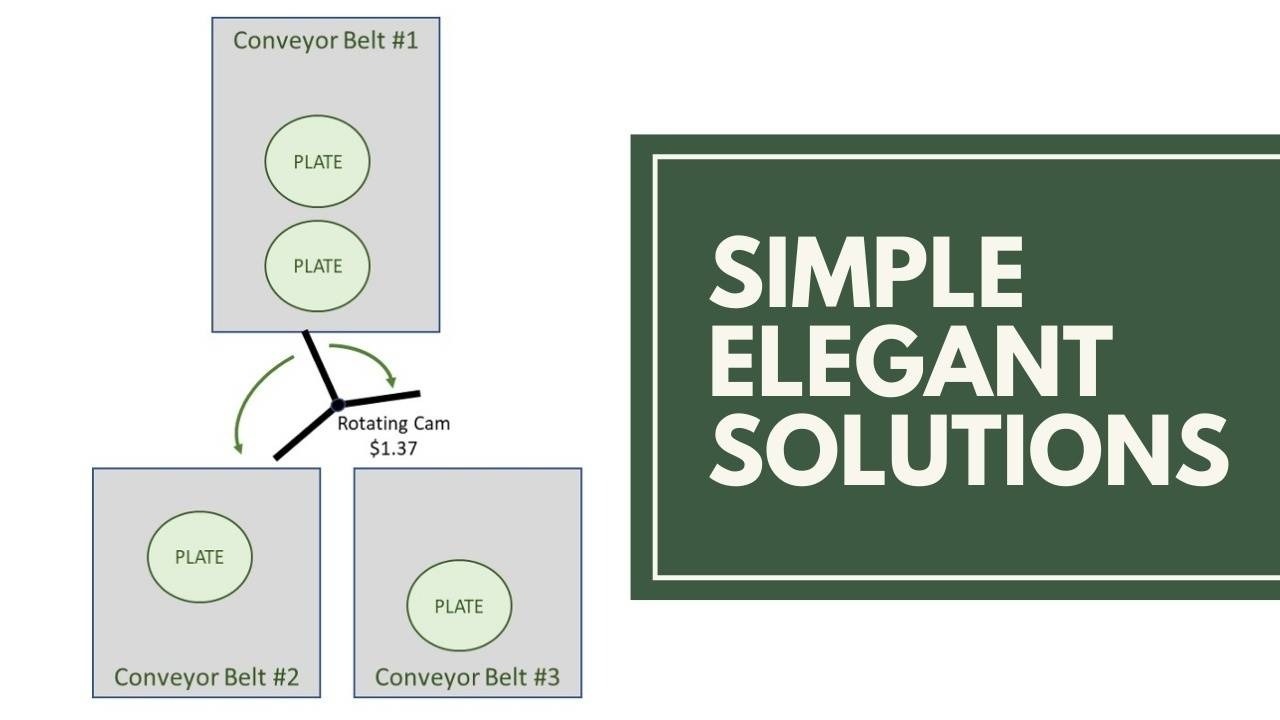

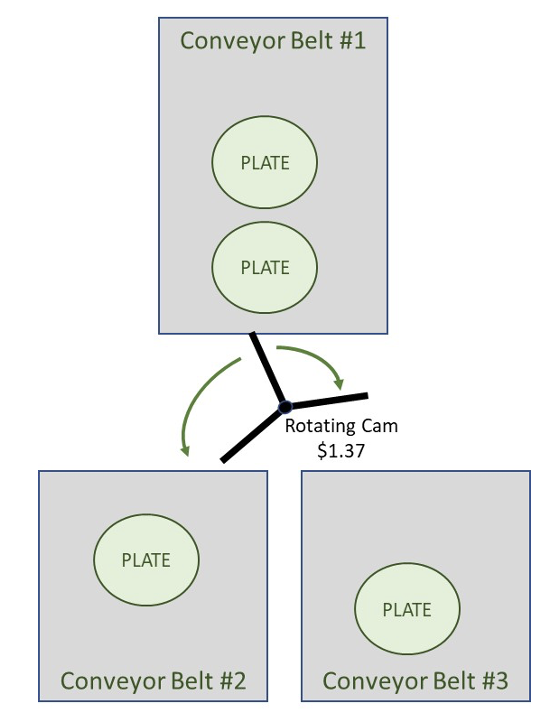

Anyway, as Pete was taking me through the plate-making plant, we stopped between conveyor belts. The first conveyor belt applied one glass layer to the plates. As the plates went to the next operation, they needed to cool slightly and move into the next stage of heat treatment at a different speed than the first conveyor. This meant that the single conveyor belt needed to divide the plates into two conveyor belts.

Pete explained that the solution provided by the first engineering team was a robotic arm with a suction cup that picks up each plate from the Conveyor Belt #1, turns left and drops it onto Conveyor Belt #2. Then the robotic arm swings back around in time to pick up the next plate from Conveyor Belt #1 and drop it onto Conveyor Belt #3.

The robotic arm would swing back and forth dividing the plates from Convery Belt #1 to Conveyor Belts #2 and #3.

The problem was that the plates developed a faint ring where the suction cup was interrupting the cooling process.

A team of engineers was deployed to investigate and solve. They analyzed the temperature of the glass coming out of Conveyor Belt #1. They looked at the minimum suction required to pick up and move the plates. They looked at minimizing the time of suction on each plate. They looked at the lengths of the conveyor belts and cooling times inside and outside the ovens.

Then they asked Pete to analyze the problem

He glanced at the operation. The robotic arm. He reviewed the calculations. And provided his solution. Instead of a $100,000 robotic arm with lots of moving parts and software, why not install a small cam that pivoted right and left. When a plate hits it, it directs the plate left. The next plate hits the cam and the plate is directed right.

$1.37 solution.

Every time I tell the story, I get teary-eyed as I think about the beautiful simple elegance of his solution.

This is one of the most important lessons I learned as a chemical engineer. Resist the urge to over-engineer your solution. Look for Simple Elegant Solutions.

Whether you're solving an engineering problem or seeking steering committee alignment, look for the Simple Elegant Solution. Believe it's there. Always. Simple Elegant Solutions require deep analysis. They require creative thinking. You'll know when you have it when you present it and everyone is silent for a moment. Gobsmacked with the simplicity.

When faced with my most complex, ambiguous challenges, I envision Pete tipping back in his chair across from me in our adjoining cubicles. He gets that smile of wisdom on his face. A glint in his eyes.

And the Simple Elegant Solution emerges.

RIP Pete

Learn Deeply and Continuously!